R & D

Yu-Chieh in Taiwan has a team of professionals with two to three decades of expertise in precision casting, machining, and inspection. They evaluate customer drawings and specialize in researching product application functionalities. Applying the five major tools of PPAP under IATF16949, along with support from APQP, FMEA, and Control Plan, they focus on studying product application functionalities. They adeptly utilize 3D mold flow software to design high-yield and defect-free production plans.

They adopt the most competitive automated production processes and efficient mold and parameter monitoring designs. They rigorously control and monitor the dimensions of high-end explosion-proof products, achieving 100% inspection and recording to ensure compliance with product application functionalities, aiming to reduce costs and increase efficiency.

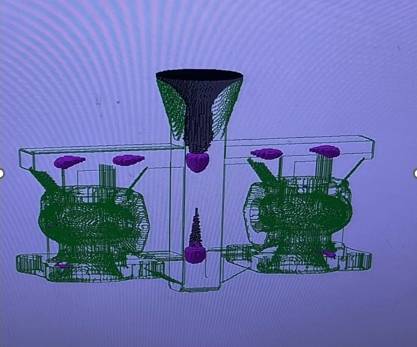

For internally complex products, they employ water-soluble wax, ceramic cores, and silica sand, applying these materials in products such as Globe Valves, Impellers, and Turbine components.

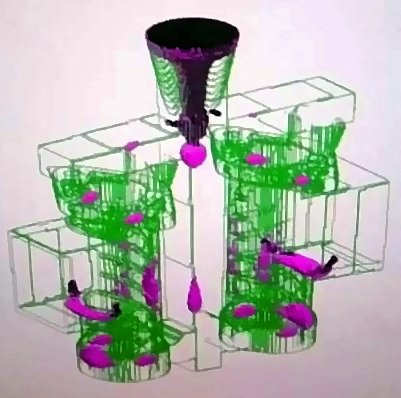

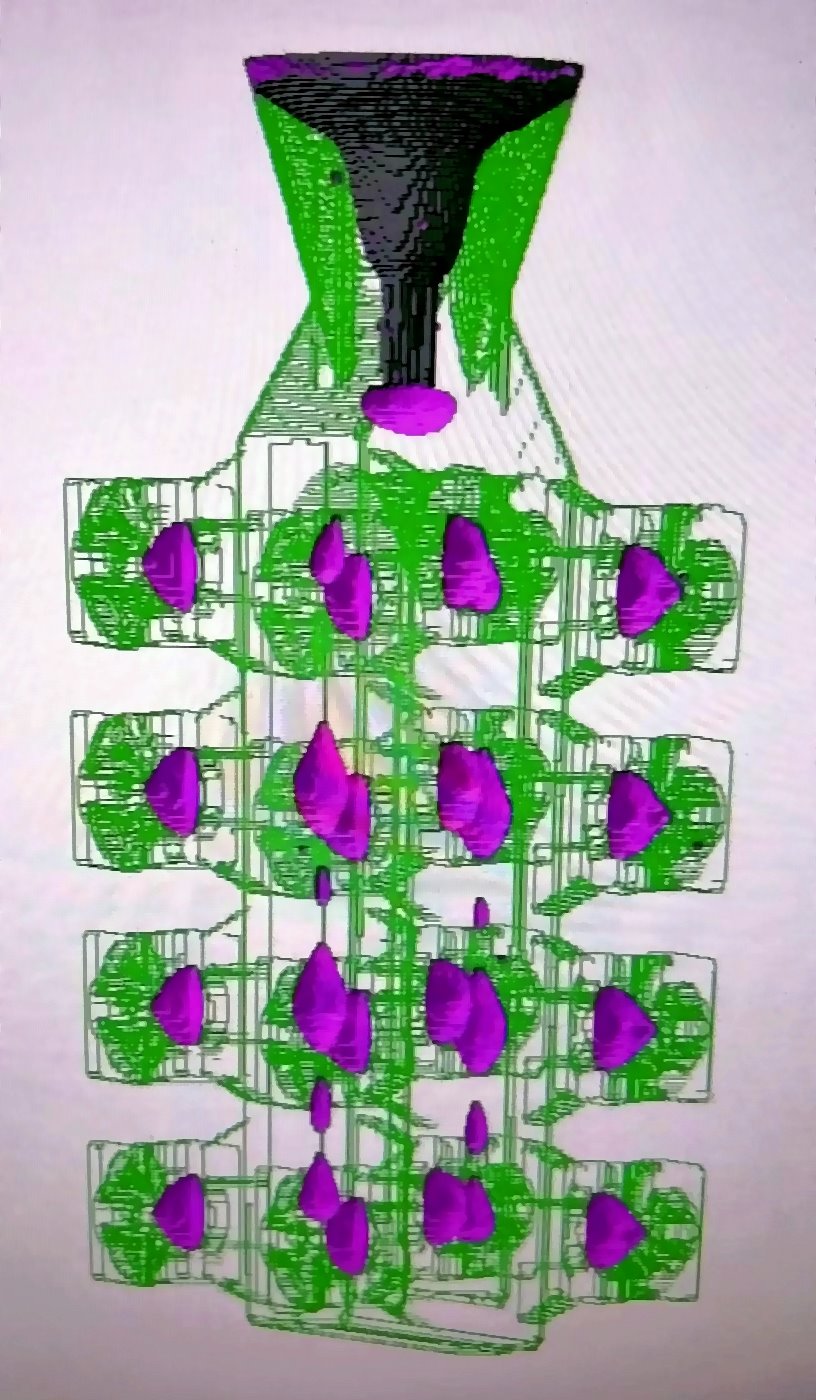

設計方案

Design Project

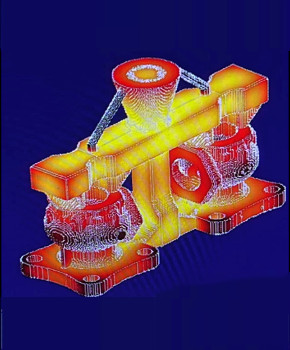

模流分析

Mold Flow Analysis

精密水熔性蠟、砂芯

Water-Soluble Wax, Sand Cores